Canaletto Tower

Design & Manufacture

Architectural Feature Cladding

Client Team

A Curved Vision

Curved façades are simple to design on paper, but far more complex to engineer and construct accurately, at Canaletto Tower the architectural challenge was not the geometry itself, but how to fabricate and install large, compound-curved aluminium panels whilst maintaining millimetre precision across the full height of a 31-storey residential building envelope without allowing cumulative tolerance, thermal creep or structural distortion to undermine the form.

Neighbourhoods In The Sky

Designed by UNStudio, Canaletto Tower introduces a fluid, layered façade that breaks the building mass into vertical clusters of three to four storeys, described by the architects as “neighbourhoods in the sky”, the façade needed to read as continuous and sculptural from all angles, with no unresolved undersides or weak junctions while remaining durable, maintainable and buildable at height.

Designing The Form

NES was appointed to design, fabricate and deliver the architectural aluminium feature cladding system that defines this identity, our scope demanded not only complex forming capability, but a fixing strategy capable of separating visual geometry from structural reality, allowing the façade to appear fluid while being supported from a rational, repeatable datum; NES developed a full 3D building envelope model in Autodesk Inventor, integrating it into the project’s BIM workflow and sharing it directly with glazing and GRC contractors, this collaborative, data-driven approach removed interface conflicts and ensured every façade element aligned seamlessly around the building perimeter.

Delivering The Vision

NES delivered approximately 4,000m² of primary architectural aluminium feature cladding, which extended to over 10,000 m² including return detail, formed into large, compound-curved panels that wrap continuously around the tower; The panels were fabricated in aluminium to accommodate tight curvature radii, long panel lengths, and controlled weight at height.

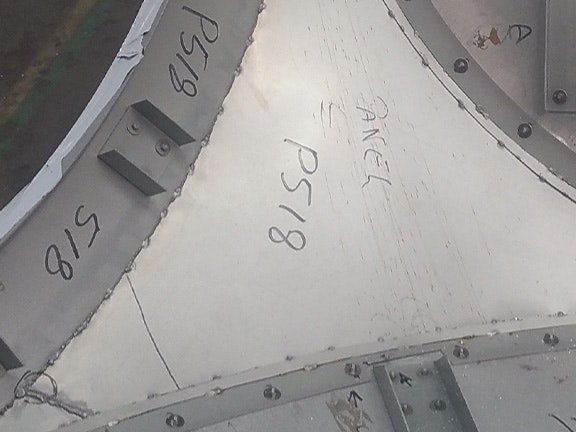

Bespoke Curved Fabrication

A key differentiator was NES in house ability to press-brake and fabricate panels up to 8 metres in length, eliminating excessive jointing and preserving the visual continuity of the façade ribbons. Panels were welded, dressed and finished to produce seamless transitions across curved surfaces, critical to maintaining the architectural intent.

Capacitor Discharge Studs

The formed panels were hung onto a secondary rail system fixed back to the structure using a hybrid approach of high-performance double-sided structural VHB tape to achieve flatness and continuous load distribution and Capacitor Discharge (CD) welded studs to prevent long-term creep from thermal movement; Given the critical structural role of the capacitor discharge studs, every one of the approximately 30,000 CD studs applied was subject to physical non-destructive torque testing, with full CE marking compliance, the level of verification required was essential to client and insurer confidence on a façade of this scale.

Fixing System

The rail fixing system was fixed back to a flat, rectangular concrete and steel datum provided by the main contractor rather than attempting to follow the complex 3D façade geometry, this separation of geometry from structure allowed accurate surveying, repeatable installation and controlled tolerances across all elevations, each 3D-formed aluminium panel incorporated internal stiffening ribs with integrated hooks, welded to the rear face, these ribs served a dual purpose: to structurally stiffen the panels for resistance of wind and snow loads and acting as the primary fixing interface.

Metallic Refraction

The external finish was a Metallic Silver Polyester Powder Coating, specified to Class 2 Qualicoat standard and backed by a 25-year AkzoNobel guarantee, selected for its ability to refract light across the compound curves to enhance depth and movement while maintaining long-term colour stability and durability in an exposed urban environment.

Interfaced Installation

The interface between the aluminium cladding and adjacent GRC elements was carefully resolved to ensure consistent alignment across materials with very different tolerances and behaviours, an issue often underestimated on free-form façades of this complexity, at the heart of the our design was the bespoke invisible hook-on fixing system, developed by NES specifically for this project;

Architecture At Height

The completed façade delivers the architectural ambition of Canaletto Tower with clarity and precision, the aluminium ribbons read as continuous and fluid elements, while the underlying fixing strategy provides robustness, maintainability and long-term performance.

Advanced Geometry

The project stands as a clear example of how advanced façade geometry can be realised without compromising buildability, durability or programme.

Similar Projects

Cladding

95 Queen Victoria Street

Get in touch with NES today to explore how our cladding solutions can transform your environment