How Perforated Cladding is Acoustically Tested

Perforated architectural cladding is often specified for its visual clarity, durability and material performance, however its acoustic behaviour is less widely understood, while perforation is commonly associated with sound absorption, the way this performance is measured and what the results actually represent is rarely explained in detail.

A step-by-step guide using real laboratory testing

This blog walks through the laboratory testing process used to measure the acoustic performance of perforated cladding, using an independent test programme carried out for NES Solutions as a real-world example; The aim is to explain what is tested, how it is tested and how the results should be interpreted.

Why perforated cladding needs acoustic testing

In buildings with large areas of metal, glass and concrete, sound reflects repeatedly from hard surfaces, this creates long reverberation times, making spaces noisy and uncomfortable, particularly where speech intelligibility is important.

Perforated panels can absorb sound, but its effectiveness depends on more than the visible perforations, the complete build-up including backing materials, air gaps and mounting method are all critical details; Acoustic testing allows this behaviour to be measured objectively, rather than assumed.

The test standard used

The testing described here was carried out in accordance with BS EN ISO 354:2003, the standard method for measuring random incidence sound absorption in a reverberation room, “Random incidence” means sound arriving from all directions, which reflects how sound behaves in real buildings rather than under controlled, directional conditions.

Single-number ratings were calculated to BS EN ISO 11654:1997, allowing overall performance to be classified in a consistent and recognisable way.

Preparing the test panels

Rather than testing a single sample, the NES Solutions test assessed multiple perforated cladding configurations to understand how different build-ups affect acoustic performance, the variables included:- Perforation format

- Thickness of acoustic insulation

- Presence or absence of a rear metal backer

- Use of a rear air void

- Mounting method

Each test panel was supplied in new condition and installed by NES Solutions for testing, ensuring the test panels reflected real construction practice rather than idealised laboratory specimens.

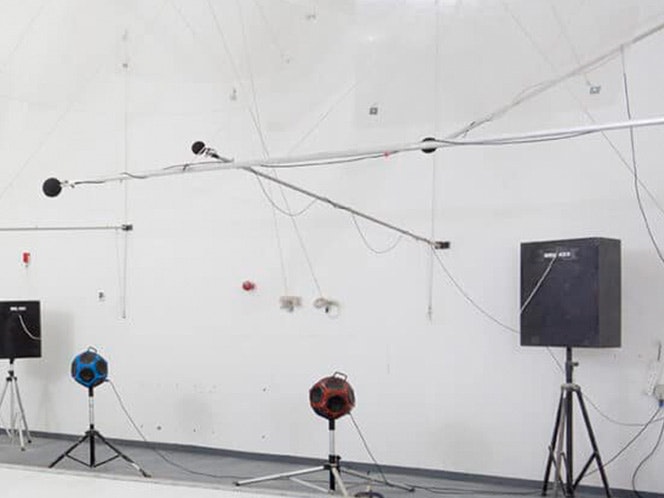

The reverberation chamber

Testing took place in a purpose-built reverberation room with a volume of approximately 300m³, the chamber is constructed from masonry and concrete and acoustically isolated from surrounding structures, internal diffusers are used to scatter sound evenly throughout the space, creating a diffuse sound field.

This environment allows accurate measurement of how quickly sound energy decays within the room.

Measuring the empty room

Before any test panels are installed, the reverberation time of the empty chamber is measured, broadband noise is generated using loudspeakers positioned at different locations, once the sound source is switched off, microphones record how long it takes for the sound level to decay by 60 dB, this time is known as the reverberation time.

Measurements are taken at multiple microphone positions and averaged to ensure consistency.

Installing the test panels

The perforated cladding test panels are then installed within the chamber, in this test programme, panels were mounted either:- Directly against a solid surface (Type A mounting)

- With a defined air gap behind the panel (Type E mounting)

- The mounting methods used reflect typical architectural installations, such as wall linings, soffits or truss enclosures.

Measuring the room with the panels installed

Once the panels are in place, the reverberation time measurements are repeated using the same procedure as for the empty room, the presence of the panels increases the amount of sound absorbed, causing the sound to decay more quickly.

By comparing the reverberation times with and without the panels, the laboratory can calculate how much sound energy is absorbed by the test specimen.

Calculating sound absorption coefficients

Sound absorption is expressed as a sound absorption coefficient (α) for each frequency band, a value of 0.0 means no sound is absorbed, a value of 1.0 means all incident sound is absorbed, measurements are taken across one-third octave bands, typically from 100 Hz to 5,000 Hz, covering the range most relevant to architectural acoustics.

In some cases, values slightly above 1.0 may occur, this is a recognised laboratory effect caused by sound diffraction at panel edges and does not indicate an error or unrealistic performance.

Interpreting single-number ratings

To simplify comparison, the measured data is summarised using:- Weighted sound absorption (αw)

- Noise Reduction Coefficient (NRC)

In the testing shown, the perforated cladding systems achieved Class A performance, the highest absorption classification under BS EN ISO 11654, this confirms that when correctly detailed, perforated architectural cladding can function as a primary acoustic absorber.

What the results show

The testing demonstrated that:- Perforated metal panels can deliver very high sound absorption

- Insulation thickness and rear air gaps significantly influence performance

- Different build-ups can be used to tune absorption across frequency ranges

- Architectural metal systems can achieve acoustic performance comparable to traditional absorbers

Most notably, strong absorption was achieved across the speech-critical frequency range, which is essential for public and commercial spaces.

Why this matters for design

Understanding how perforated cladding is tested helps designers make informed decisions.

Rather than treating acoustic performance as an assumption or a secondary benefit, laboratory testing provides measurable data that can be used in acoustic modelling, specification and performance verification, it also reinforces the importance of considering the entire system, not just the visible perforated face.

Closing thought

Acoustic testing turns perforated cladding panels from a visual feature into a measurable performance element.

By understanding the process, from reverberation room measurement to performance classification, architects and consultants can specify perforated metal systems with greater confidence.

The testing shown provides a clear example of how architectural cladding systems are assessed and why independent laboratory testing remains essential in performance-led design.