Anodised Aluminium in Architecture

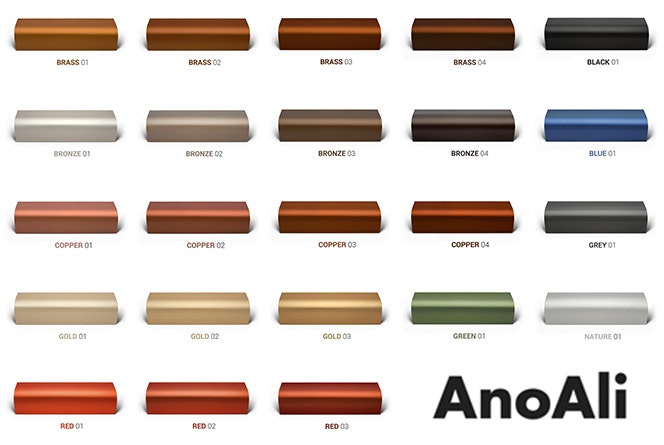

Choosing the right anodised aluminium finish can be challenging, from colour and texture to durability and sustainability, there’s much to consider. Written for architects, façade consultants and specifiers working on external cladding, rainscreens and architectural metalwork, this guide aligns with recognised European quality frameworks such as QUALANOD and BS EN ISO 7599. Where relevant, it draws on our NES "AnoAli" anodised aluminium range, manufactured and controlled end-to-end to deliver predictable architectural outcomes.

Anodising elevates aluminium beyond its raw industrial form

Transforming it into a high-performance architectural material with exceptional durability and design versatility, at NES we have our own AnoAli range of anodised aluminium finishes.

Premium Finish?

Anodised aluminium is often specified as a “premium metal finish” yet it remains one of the most misunderstood façade materials. Unlike paint or powder coating, anodising is not applied to aluminium, it is a controlled electrochemical conversion of the metal itself, our range is achieved through a controlled electrochemical process, the surface of the aluminium is converted into a robust oxide layer, integral to the metal itself rather than applied on top. This creates a finish that will not peel, flake or blister, offering long-term resilience against weathering, UV exposure and environmental pollutants.

A Legacy of Finish, Guaranteed for Generations

The result is a refined surface available in a range of tones and textures, from natural silver and bronze through to deep black, supported by a 20 year guarantee on all colours Qualanod and a 40 year guarantee on all colours BS 3987, with an expected lifespan of more than 80 years.

Anodised Finishes That Harmonise

The anodised layer enhances both form and function, delivering a consistent satin appearance that complements contemporary architectural materials such as glass, stone and steel.

Eco-Conscious with a Lasting Impact

Beyond aesthetics, anodised aluminium aligns with modern sustainability goals. The process is environmentally responsible, generating minimal waste and producing a finish that significantly extends the product’s lifespan, reducing maintenance and replacement cycles.

Engineered Aluminium for Iconic Architecture

Ideal for architectural cladding & façades signage, anodised aluminium combines precision engineering with timeless visual appeal. A specification choice where design integrity and performance are equally essential.

1. What Anodised Aluminium Actually Is

Anodising is an electrochemical process that thickens aluminium’s naturally occurring oxide layer. This oxide is not a coating; it is chemically bonded to the substrate and grows both inward and outward from the base metal. The resulting anodic layer is:- Integral to the aluminium, it cannot peel or flake

- Ceramic in nature, hard, inert and UV-stable

- Microporous, allowing controlled colouring and sealing

- Architectural anodising is governed by standards such as QUALANOD, which define requirements not only for nominal thickness but also for appearance, uniformity, sealing quality and inspection regimes.

- Anodised aluminium is optical, not opaque.

2. Why Architects Choose Anodised Aluminium

- Appearance

- Anodising is specified for its performance and aesthetics.

- Long-Term Colour Stability.

- Authentic Metallic Appearance.

- Light penetrates the oxide layer, reflects from the aluminium substrate and returns through the oxide, creating depth and subtle variation that coatings cannot achieve.

- Its characteristics cannot be replicated by paints, varnishes or lacquers.

- Produced and sealed to recognised quality standards, Anodised Aluminium remains colour-stable for decades.

- Low Maintenance

- The anodic layer is highly resistant to abrasion, finger marking, salt spray and urban pollution.

- Anodised aluminium used in architecture requires very little maintenance, the anodising layer consists of metal, aluminium oxide and is hard and robust.

- In most UK environments, anodised aluminium requires only periodic washing with water and mild detergent, there is no repainting or recoating cycle.

- A clean anodised aluminium surface has a very long lifespan, under normal conditions it can easily last 80 years without losing its gloss or colour (e.g. the electrolytically dyed layers).

- Sustainability

- Anodising adds negligible material mass, contains no VOCs and does not compromise aluminium’s recyclability measured over its service life. Often exceeding several decades, anodising typically has a lower environmental footprint than high-performance coating systems.

3. How Colour Is Created in Anodised Aluminium

Anodised aluminium does not have “paint colours” in the conventional sense. Its tone results from the interaction of three variables:- Aluminium alloy composition

- Anodic layer thickness and pore structure

- Colouring method (organic dye or electrolytic metal deposition)

Metal Salts, Not Pigments

Architectural anodised colours, bronzes, blacks, greys and natural metallic tones are typically achieved with oxide pores and not surface pigments. With no pigments present in the finish, anodised surfaces cannot fade, which is why it offers exceptional UV stability

Colour Tolerance

Whilst the anodic layer thickness can improve corrosion protection, beyond an optimum range it does not necessarily enhance performance and may affect visual uniformity if not properly controlled. Following QUALANOD and BS quality standards, AnoAli will provide a colour tolerance range to be agreed with the client team as part of the specification, ensuring the required performance and appearance.

4. Controlling Tone, Gloss and Visual Consistency

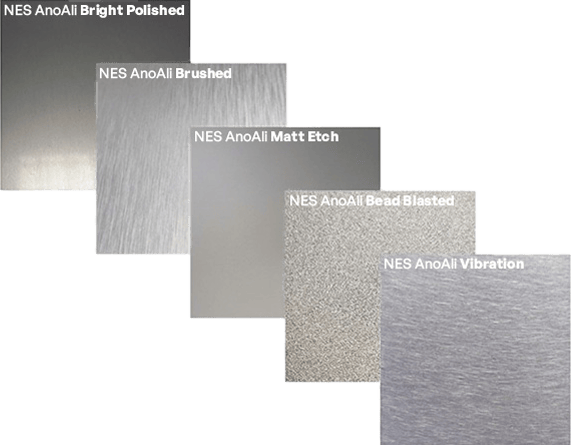

Anodised aluminium is not visually flat, its appearance shifts with viewing angle, sun position, surface texture and grain direction, this is inherent to the material and not a defect but it must be controlled via surface preparation before anodising noting that whatever texture exists before anodising remains visible afterwards. Common architectural preparations include:- Bright Polished, high reflectivity, typically for feature elements

- Brushed, directional, often used internally

- Matt Etch, low gloss, suited to galleries and minimal architecture

- Bead Blasted, low-gloss surface reducing grain, increasing strength and scratch resistance which can also be used with masks to create patterns and images.

- Vibration, non-directional, lightly textured finish minimising fabrication marks

5. Anodic Layer Thickness, Tolerance and Sealing

Anodic layer thickness is specified in microns (µm) under systems such as QUALANOD and BS EN ISO 7599. Our AnoAli range can offer the following layer thicknesses:- A5 (5 µm) - Indoor use

- A10 (10 µm) - Indoor use (standard indoor use)

- A15 (15 µm) - Outdoor use

- A20 (20 µm) - Outdoor use (EU standard)

- A25 (25 µm) - Outdoor use (Coastal / British standard)

- Thickness measurement and tolerance requirements

- Sealing quality tests (such as mass-loss or dye-spot tests)

- Visual inspection criteria

- Proper sealing is critical, advanced sealing methods including enhanced hot-water or proprietary sealing processes significantly improve corrosion resistance and long-term performance in demanding environments.

6. Fabrication, Edges and the Risk of “Silvering”

Silvering is directly attributed to fabrication processing, not an anodising failure.- "Silvering" is the appearance of bright aluminium at cut edges, folds or machined areas, it occurs when fabrication is carried out on pre-anodised materials.

- Knife folding, brake press folding and cutting of components post anodising breaches the oxide layer, because the anodic layer is hard and ceramic any sharp folds can cause micro-cracking and is particularly visible on dark bronze and black finishes and can slightly affect the aesthetical appearance due to "crazing", however the resistance to corrosion will not be affected.

- NES apply a polyurethane film between the press brake tooling and the external “seen face” of the anodised aluminium. This prevents the sensitive anodised face from picking up tool mark in the folding process.

- We can provide assistance if pre-anodised materials are your preferred choice, we can offer advice and provide specifications to suit your project.

- As a rule of thumb the minimum inner bending radius at 90° would be 1t which is one times the thickness of the material, so for 3mm 5005A H14 aluminium the internal radius would be 3mm and external approx. 6mm, in line with EN 485-5.

7. The NES Way

By following our fabrication sequence for high-quality architectural results "silvering" is avoided, our process includes:- Designing the correct bend radii and edge detailing

- Cutting, folding, routing and/or punching components first

- Folded return edges for stiffness and visual quality

- Cleaning and preparing the final component to high standards

- Anodising the completed components as per QUALANOD and BS standards

- Sealing and inspecting under grazing light

- This process ensures full oxide coverage around edges, returns and complex geometry

8. Managing Colour Consistency on Large Projects

Consistency in anodised aluminium is primarily a project-management challenge, not just a material one, best practice includes:- Early full project batch procurement of material to avoid inter-batch variation

- Assigning coil batches to elevation

- Defining unavoidable grain rotation locations

- Defined colour tolerances rather than “exact match” expectations

- A single anodiser for all visible elements

- Full-scale mock-ups

9. Cleaning

Project-specific cleaning and maintenance guidance is provided as part of the operations and maintenance manual, as a guide we recommend the following cleaning regime:- Coastal or polluted environments, every 6–9 months

- Urban environments, every 12–18 months

10. AnoAli by NES

AnoAli our anodised aluminium range, developed for architectural applications where colour control, edge quality and long-term performance are critical, key characteristics:- Architectural-grade alloy selection

- Post-fabrication anodising as standard

- A25 (25µm) anodic thickness

- Controlled batching and elevation management

- Technical support at design and detailing stage

11. NES AnoAli Anodising Process:

A. Mechanical Pre-Treatment

B. Chemical Pre-Treatment

C. Anodising (Electrochemical Oxide Formation)

D. Colouring

E. Pre-Sealing (AnoAliGuard)

F. Sealing